BRS Biotech Company has delivered and put into operation the unique fermentation complex.

The fermentation complex is comprised of:

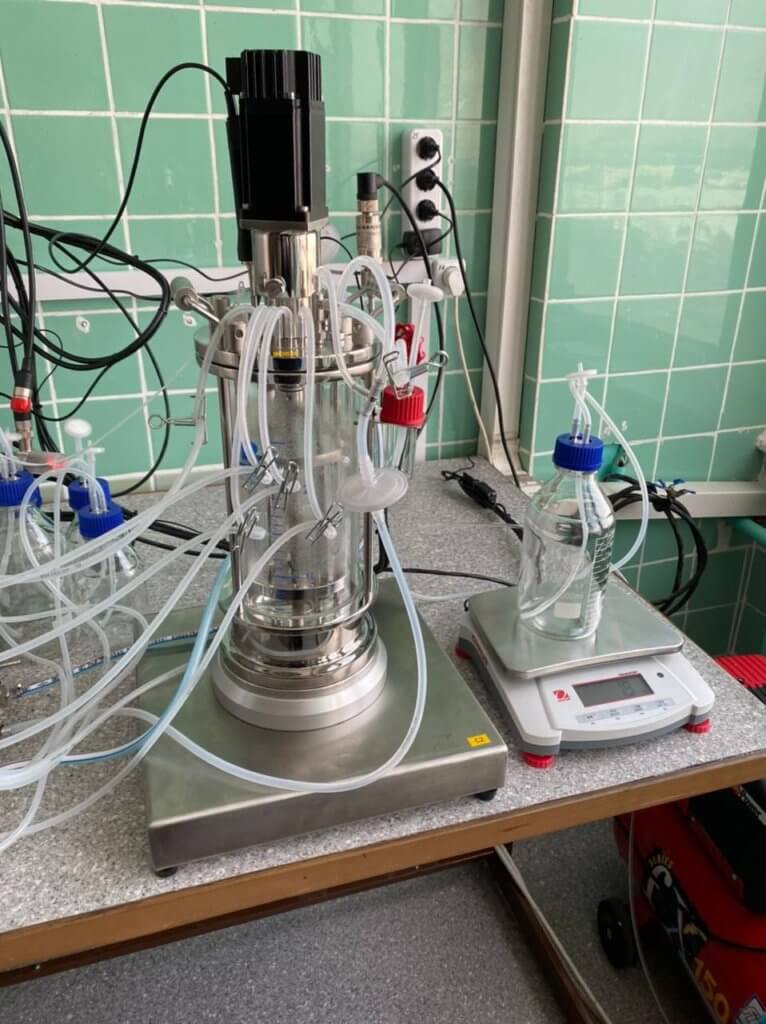

A desktop bioreactor with two autoclavable glass vessels of 3 liters in an extended configuration:

• mixer speed control (1,500 rpm)

• aeration control by a rotameter (1 pc. per a vessel)

• pH control/transmitter Mettler Tolledo

• DO control/transmitter Mettler Tolledo

• pressure measurement sensor

• Five Watson-Marlow peristaltic pumps at a constant speed

Additional options:

– the measurement and maintenance of the specified concentration of methanol dissolved in the culture liquid. The measurement range is 0-10,000 ppm.

– the feeding measurement and control – the OHAUS scales

– the remote operator workplace, including a laptop, OPC server for remote working on the fermenter, Scada advance program.

The fermenter, equipped according to the customer’s requirements, will be used to provide the scientific and research paper:

The obtaining of a feed enzyme preparation of β-mannanase using a recombinant yeast producer

Enzyme preparations are now extensively used in forage production to improve the nutrition value of forage and to reduce the cost of livestock production. The main component of forage for farm animals is plant products (grain crops, a silage, a roughage, etc.), which contains quite a few of indigestible substances – a cellulose, a lignin, a hemicellulose, etc.

In order to improve the digestibility and to increase the efficiency of the use of plant forages, the enzyme preparations (0.1-1.5% of the dry mass of a forage), which have been obtained with the help of microorganisms, and which contains active complexes of hydrolytic enzymes, are added to the ration of farm animals. One of these enzymes is β-mannanase, which cleaves β-(1.4)-O-glycosidic bonds in mannans, making them available for the assimilation by farm animals. We are looking forward to the results of the researches carried out using our equipment.