Our company’s engineers have successfully finished installation of two bioreactors for research work at the client’s site:

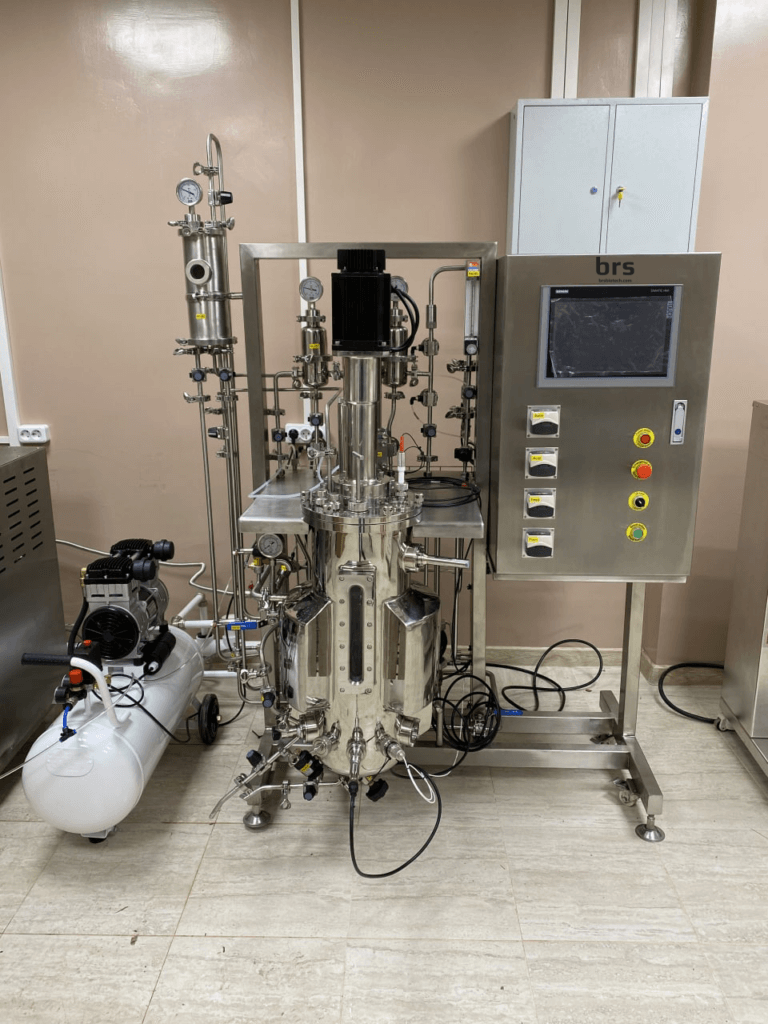

1. The bioreactor with the total volume of 30 liters for classical microbiological synthesis.

The software makes the entire fermentation process automatic: the pH, DO, temperature and mixing speed are controlled through the controller; peristaltic pumps located on the front side of the control unit ensure timely feeding of acid, alkali, defoamer and nutrient medium.

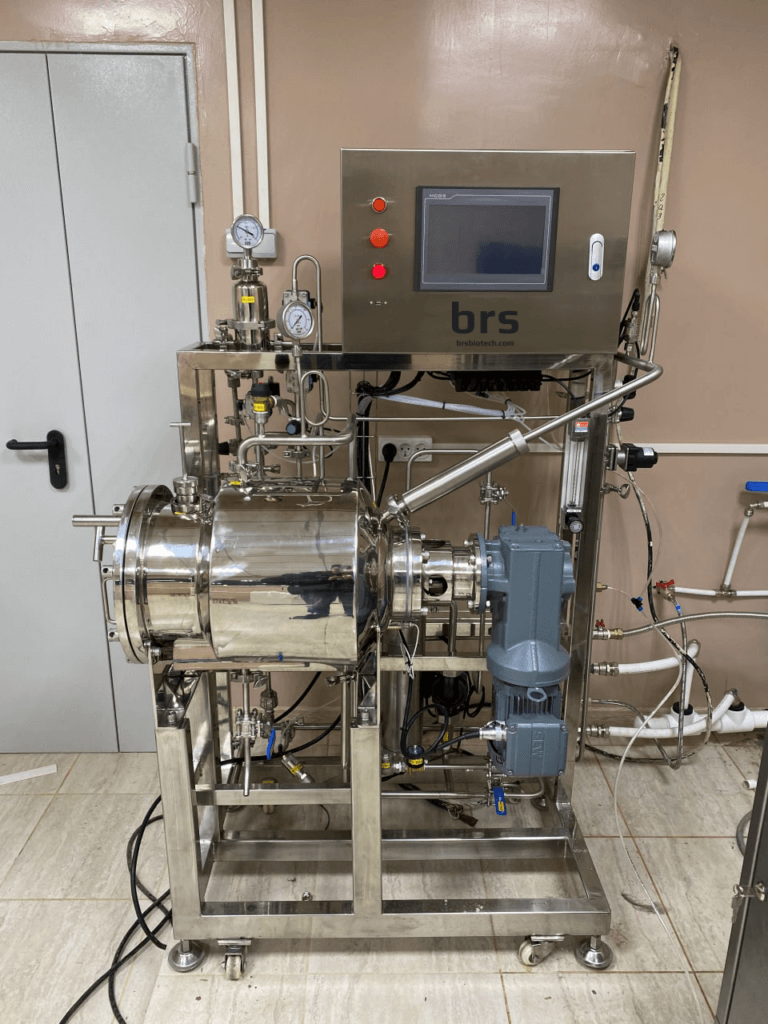

2. Solid state fermentation bioreactor with the total volume of 20 liters

Solid state fermentation allows the cultivation of microorganisms on solid substrates with a low moisture content. Solid state fermentation bioreactors are used in the production of medicines, feed, enzyme preparations, biopesticides, etc.

In comparison to the bioreactor for classical microbiological synthesis, the mixing system of the solid state fermentation bioreactor has an L-shaped drive; the agitator shaft and ribbon-blade agitator are made of 316L stainless steel.

The control system is adapted to various types of sensors and actuators, input/output signals. It has the functions of recording and registration, setting up sequences (recipes). The data saving format is compatible with EXCEL, it allows fast copying to an external USB drive. To understand the working state of various nodes, a simulation of the workflow is displayed on the controller.